CO2 Ice

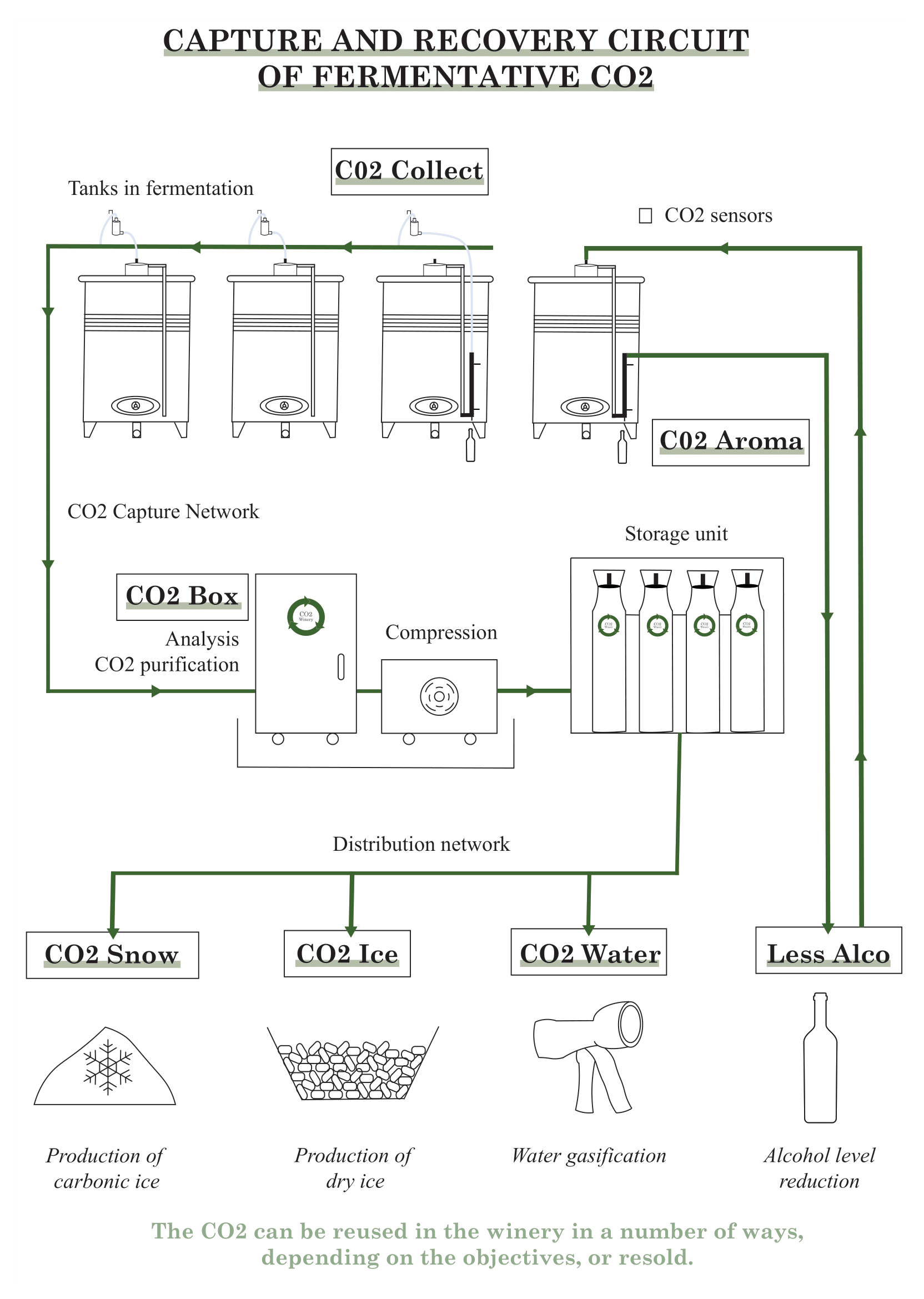

CO2 Winery transformsfermentative CO2 from vats into a valuable resource for winemakers.

Thanks to our CO2 Box, we analyze, purify, and compress this gas, which is then stored safely in storage racks, ready for reuse. This approach is part of a circular economy approach, reducing CO2 losses and transforming this waste into an asset for the winery.

One of the upgrading processes we propose is the production of dry ice.

Find out more about the benefits of dry ice for winegrowers.

Our system for producing dry ice in pellets is an efficient, easy-to-use cooling medium for the crucial stages of winemaking.

However, dry ice, often compared to ice cubes, is much cooler, with a temperature of -78°C. It sublimates - i.e. goes directly from solid to gaseous state - without leaving any residue, offering a convenient and clean cooling method. As it sublimates, dry ice produces a cooling effect that effectively protects vendanges and vin from oxidation by forming a layer of CO2 on the surface.

Dry ice is used for several essential applications in the winery:

- Inerting presses and tanks: protects against oxidation by creating an inert atmosphere.

- Pre-fermentation maceration: temperature control for better extraction of aromas and tannins.

- Harvest cooling: maintains grape freshness for optimum quality.

- Harvest protection: prevents oxidation of the grapes and preserves their integrity.

This production system for dry ice meets the requirements of a modern viticulture offering a solution for efficient cooling, protector and respectful of the quality from harvest.